Insulated Render

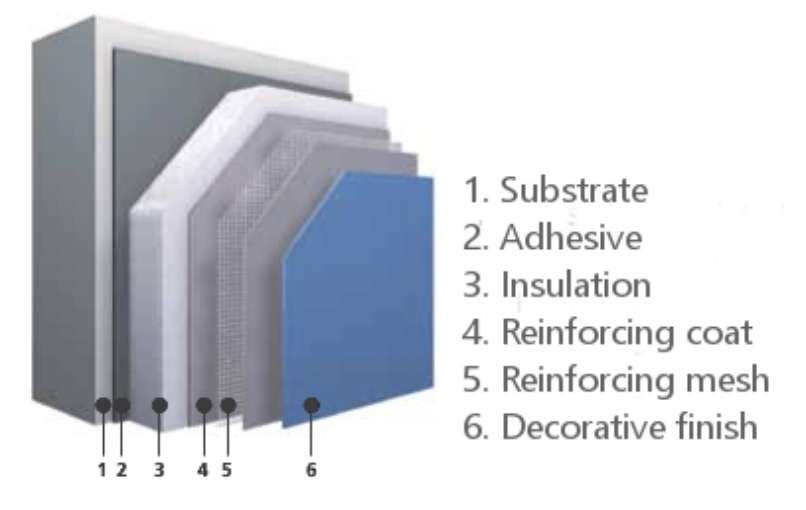

An insulated render system is a multi-layered approach to thermal insulation applied to the exterior of a building. These systems help improve thermal efficiency and enhance energy performance while protecting the building façade. It typically involves the following layers:

- Rigid Insulation: This layer consists of boards or sheets that provide thermal insulation.

- Reinforcing Mesh: Applied over the insulation, this mesh enhances structural integrity.

- Render Base Coat: A layer of base coat material is applied to the mesh.

- Finishing Coat: The final layer is a protective render finish.

Insulated render systems are commonly used for improving thermal efficiency and enhancing energy performance in buildings.

- Insulation: The core component of an insulated render system is the insulation material. Common options include:

- Expanded Polystyrene (EPS): Lightweight and easy to install, EPS slabs are mechanically fixed to the existing wall.

- Mineral Wool Slab: Provides good thermal performance and fire resistance.

- Phenolic Foam Slab: Offers excellent insulation properties.

- Mechanical Fixings: These are used to attach the insulation boards to the wall. They can be made of metal or plastic. To minimize thermal bridging, adhesive-fixed insulation or a track & rail system can be used.

- Mesh Reinforcement: A mesh is applied over the insulation to create a key backing for subsequent layers.

- Render Base Coat: This layer provides a smooth surface for the final finish. It’s typically applied over the mesh.

- Finish Coat: The outermost layer is the decorative render finish.

- Silicone Render: Durable and water-repellent.

- Mineral Render: Breathable and natural-looking.

- Polymer Plain Render: Versatile and available in various colors.

- Polymer Dashing Render: Textured finish with added aggregates.

- Rendabrick: Simulates brickwork appearance.

- Acrylic and Silicate Renders: Different finishes for aesthetic variety.

- EPS (Expanded Polystyrene) System:

- Prepare the Surface: Clean and repair the existing wall surface.

- Fix Insulation Boards: Mechanically fix EPS insulation boards to the wall using appropriate fixings (screws or nails).

- Apply Base Coat: Apply a base coat (usually cement-based) over the insulation boards.

- Install Reinforcement Mesh: Embed a fibreglass mesh into the base coat while it’s still wet.

- Apply Finish Coat: Once the base coat is dry, apply the final decorative render finish (e.g., silicone render, acrylic render).

- Mineral Wool System:

- Surface Preparation: Clean and repair the wall.

- Attach Insulation Slabs: Fix mineral wool slabs to the wall using adhesive or mechanical fixings.

- Base Coat Application: Apply a base coat (cementitious or polymer-based) over the insulation.

- Mesh Reinforcement: Embed a mesh into the base coat.

- Final Render Coat: Apply the chosen render finish (e.g., mineral render, acrylic render).

- Phenolic Foam System:

- Surface Preparation: As with other systems, prepare the wall.

- Fix Phenolic Foam Slabs: Attach phenolic foam slabs using mechanical fixings.

- Base Coat and Mesh: Apply a base coat and embed reinforcement mesh.

- Finish Coat: Apply the desired render finish.

The finish coat in an insulated render system is the outermost layer that provides both aesthetic appeal and protection.

- Types of Finish Coats:

- Silicone Render: Durable, water-repellent, and available in various colors.

- Mineral Render: Breathable and natural-looking.

- Acrylic Render: Versatile and easy to apply.

- Polymer Plain Render: Offers different finishes for aesthetic variety.

- Polymer Dashing Render: Textured finish with added aggregates.

- Rendabrick: Simulates brickwork appearance.

- Application Process:

- After applying the base coat (which provides a smooth surface), the finish coat is applied.

- It can be trowel-applied or sprayed onto the surface.

- The thickness of the finish coat varies based on the system and manufacturer’s recommendations.

- Benefits:

- Weather Resistance: Finish coats protect against rain, UV exposure, and temperature fluctuations.

- Decorative: They enhance the appearance of the building.

- Breathability: Some finishes allow moisture vapour to escape while maintaining water resistance.

CHOOSE MANUFACTURERS

There are no products to list in this category.